Q. What is the Shur-Shot?

A: The Shur-Shot is used to detect gross leaks of Hydrogen Fluoride (HF) in the vapor phase. It is based on an optical technique, which senses the etch rate of a special coating on the sensor tip by HF. It most commonly mounted in close proximity to devices where HF leaks are likely to occur, such as valves, seals etc. In these locations, even a tiny drop of liquid HF will form a very high localized concentration of HF, which is detected by the Shur-Shot. These types of leaks are often not detected by ambient air HF sensors such as IMS or electrochemical cell ppm level analyzers, as the vapors are often diluted by wind to sub-ppm levels just a few feet away from the leak. In this way, failing seals can be detected before a catostrophic leak occurs.

The Shur-Shot is a complimentary technique, often used in conjuction with ambient air and open path sensors as part of a comprehensive safety system. It is most often employed in petrochemical alkylation plants, but is suitable for any facility where large quantities of HF are stored or used.

Â

Q: How reliable is the Shur-Shot?

A: The Shur-Shot is extremely specific to HF. HF is the only compound that can etch the special coating of the sensor. In 15 years of use, no false alarms or missed events have ever been reported .Â

Â

Q: Is the Shur-Shot quantitative?

A: No. It is designed to be a "go/no go" leak detector.Â

Â

Q: What is the output signal?

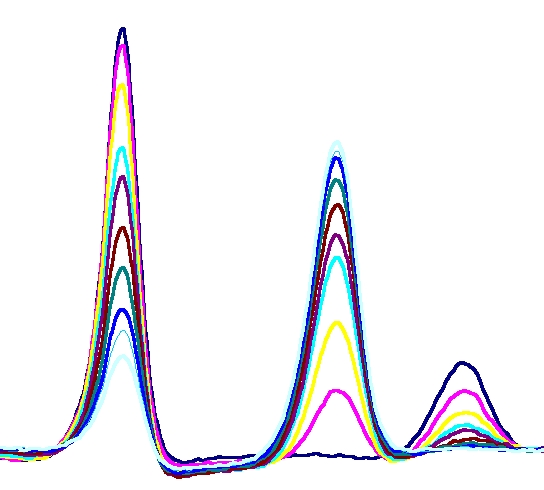

A: The device uses a 4-20 mA loop. When a new sensor is installed, the device is adjusted to give an output of 8 mA. As long as no HF is present, the device will ouput a constant 8 mA. The presense of HF etches the sensing element, causing an increase in the output signal. This is an irreversible effect, so that the output is proportional to the total cumulative amount of HF exposure.

Over time, (typically months) low ambient levels of HF will slowly etch the sensor, causing a slow rise in output signal. A slow rise to 10 mA indicates low ambient levels of HF, which should be set in the DCS as a maintenance alarm point. At 10 mA, the sensor should be replaced. This maintenance is critical to differentiate between slow etching due to ambient levels vs. a true alarm.

In the case of a true leak, the output will quickly rise to over 12 mA, which should be set as the high alarm point. Â Â

ShurShot Hydrogen Fluoride Leak Detector

ShurShot Hydrogen Fluoride Leak Detector